Portable Powder Coating Equipment has become a game-changer in the world of powder coating, offering convenience and flexibility like never before. As a seasoned DIY enthusiast put it, "The

Portable Powder Coating Equipment I got has allowed me to take my projects to the next level, giving me professional-looking finishes right in my own garage." Another user from a small-scale business shared, "Our portable powder coating equipment has been a lifesaver, enabling us to handle on-site jobs with ease and efficiency."

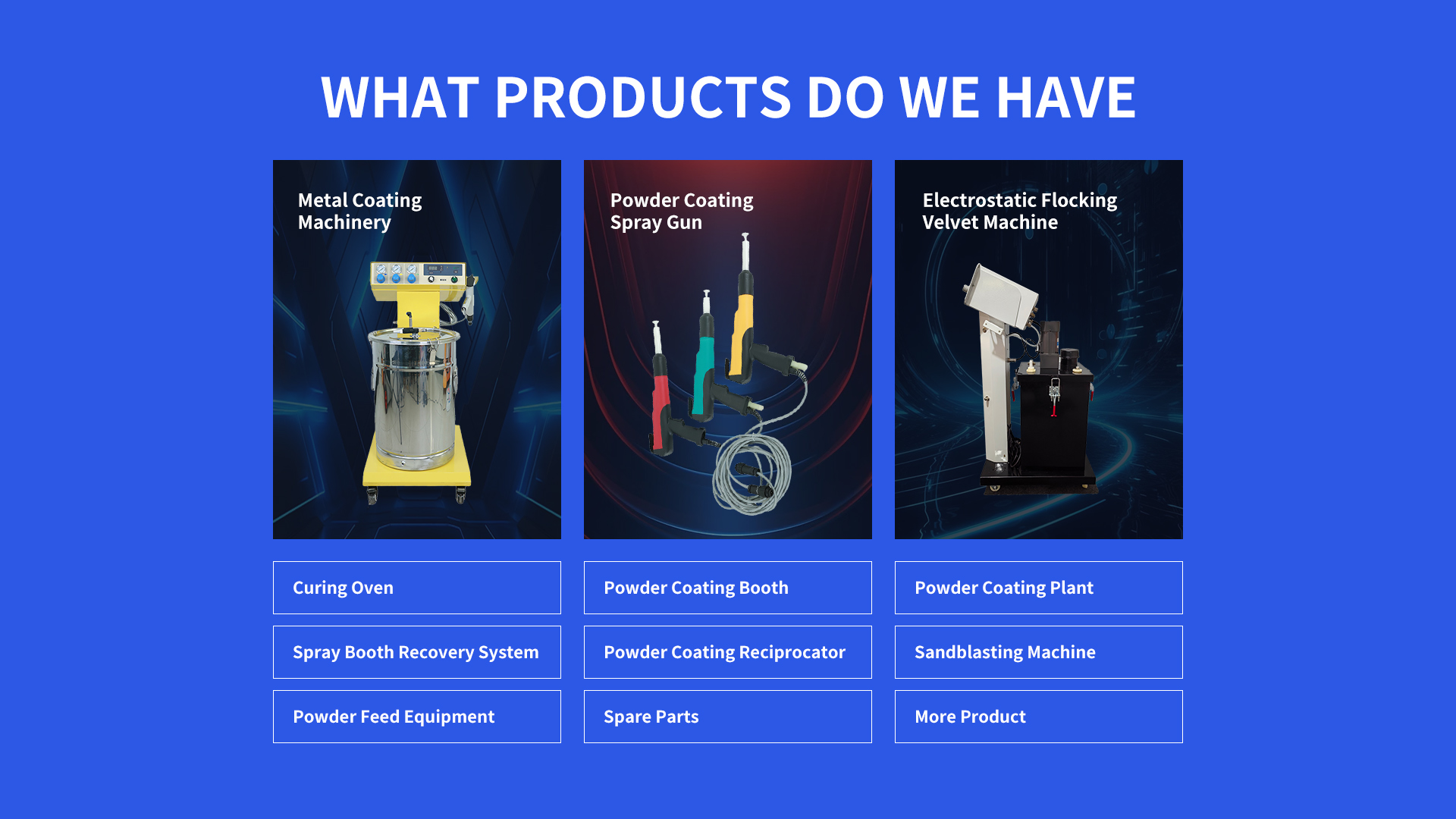

Portable Powder Coating Equipment typically consists of a compact powder coating gun, a small powder feeder, and sometimes a portable curing unit.

The powder coating gun features a handle for easy grip, a powder flow control mechanism, and a nozzle. In electrostatic models, there is an electrostatic charging system to enhance powder adhesion. The powder feeder is designed to be lightweight and portable, with a hopper to store powder and a mechanism to regulate the powder flow. Some portable units may come with a small, transportable curing oven made of lightweight yet heat-resistant materials, which has basic heating elements and a simple circulation system.

These portable units are ideal for DIY projects at home, such as coating small metal items like garden tools, bicycle parts, or home decorations. Small-scale workshops can use them for on-site jobs, like coating metal structures at construction sites or refinishing metal furniture at clients' locations. Automotive repair shops can also benefit from portable powder coating equipment for touch-up jobs or coating small components away from the main workshop.

The price of

Portable Powder Coating Equipment can vary. Basic portable sets, suitable for hobbyists or occasional use, can range from $300 to $1000. These usually include a simple powder gun and a basic powder feeder. Mid-range portable equipment, with better quality components like electrostatic guns and more efficient powder feeders, costs between $1000 and $2500. High-end portable units, which may come with advanced features like a portable curing oven and precise control systems, can exceed $2500.

Before use, assemble the equipment according to the instructions and ensure all connections are secure. Fill the powder feeder with the appropriate powder. Adjust the powder flow rate and, if applicable, the electrostatic charge settings based on the workpiece. Hold the gun at a consistent distance (around 15-20 cm) from the workpiece while spraying. If using a portable curing unit, place the coated item inside and follow the recommended curing temperature and time settings.

Consider your specific needs. If you mainly do small-scale DIY projects, a basic portable set may be sufficient. For more professional or on-site work, look for equipment with features like electrostatic charging and a portable curing oven. Evaluate the weight and size of the equipment for easy portability. Also, check the reputation of the manufacturer and the availability of after-sales support.

Wear a dust mask, safety goggles, and gloves to protect against powder inhalation and potential splashes. Ensure proper ventilation in the work area, especially when using a portable curing unit. Keep the equipment away from flammable materials and sources of heat when not in use.

The design of

Portable Powder Coating Equipment is rational as it offers mobility and flexibility. The compact size and lightweight nature make it easy to transport and store. The ability to perform powder coating tasks on-site or in small spaces saves time and effort. The adjustable features of the equipment allow for customization according to different projects, ensuring efficient and high-quality results.

Q: What if the powder coating is uneven with my

Portable Powder Coating Equipment?

A: Check the powder flow rate and adjust it if needed. Also, make sure the gun is held at a consistent distance and angle from the workpiece. If it's an electrostatic model, verify the electrostatic charge settings.

Q: Can I use different powder types with my Portable Powder Coating Equipment?

A: Yes, but it's essential to clean the equipment thoroughly between different powder types to avoid contamination, which could affect the coating quality.

Q: How often should I maintain my Portable Powder Coating Equipment?

A: Clean the powder gun, feeder, and any other components after each use to prevent powder buildup. Periodically check and service the electrostatic charging system (if applicable) and the heating elements in the curing unit.

Q: What if the portable curing unit doesn't reach the required temperature?

A: Check the temperature settings and ensure the unit is properly plugged in. If the problem persists, contact the manufacturer's customer service for assistance.

Q: Can I upgrade the features of my Portable Powder Coating Equipment?

A: In some cases, it may be possible to upgrade certain features, such as adding an electrostatic charging kit or improving the powder feeder. However, this depends on the design and compatibility of the equipment. It's best to consult the manufacturer for advice.

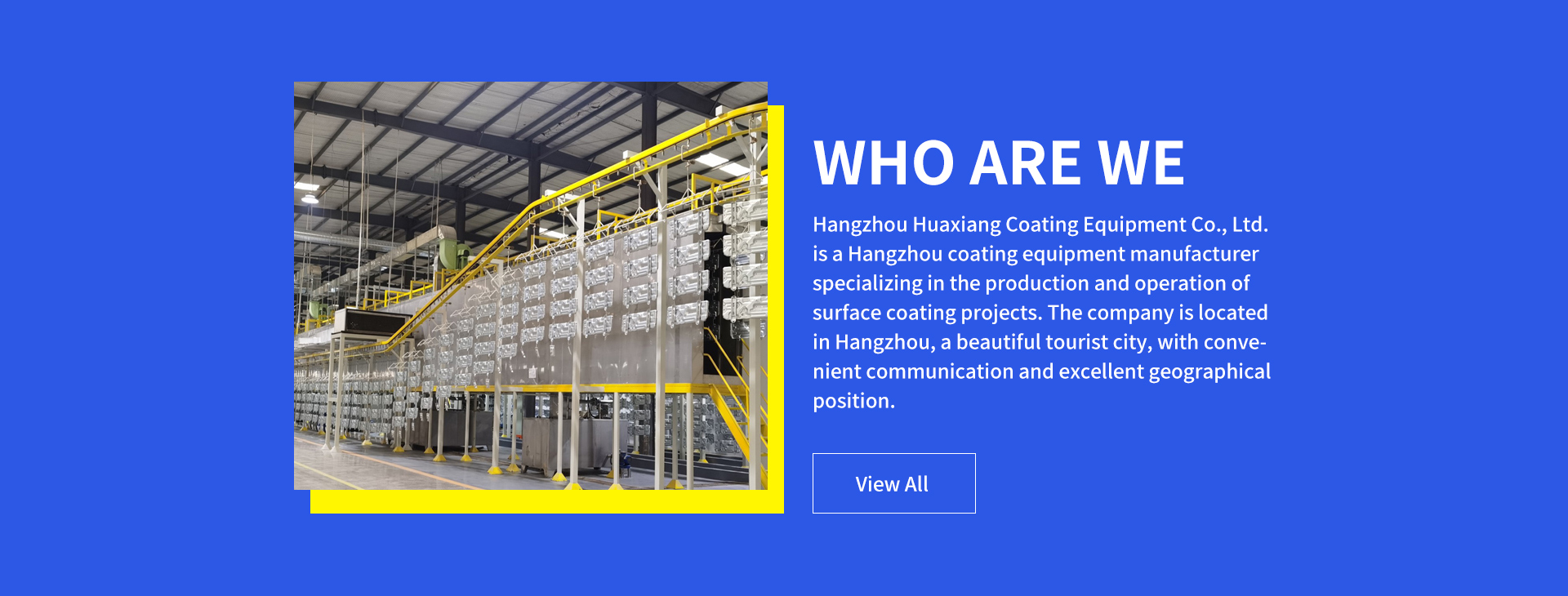

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com